Contents

Stickers are a handy and affordable way to boost your brand, add a cool vibe to your belongings, or simply stand out. They come in every kind you imagine, and can be made from tons of materials.

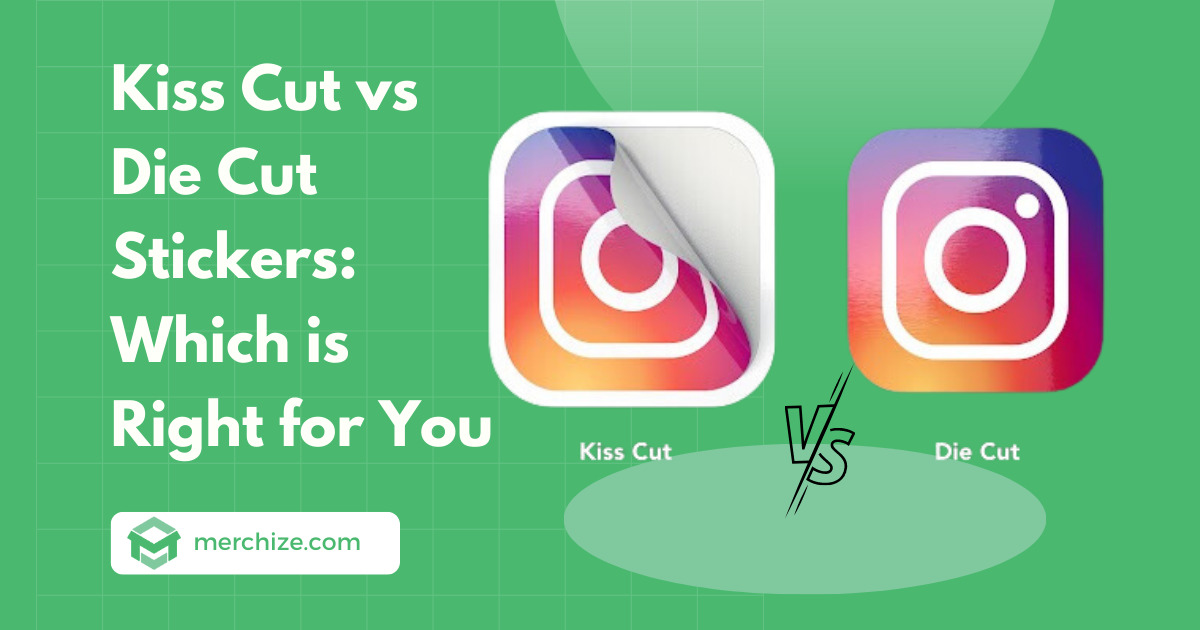

When choosing stickers for your print on demand business, one of the most important decisions you’ll need to make is whether to go with kiss cut or die cut stickers. Both types of stickers have their pros and cons, so you gotta know the difference between them before you make a decision.

In this blog post, we’ll dig in at kiss cuts and die cuts stickers, and help you decide which is right for your print on demand sticker products of your business.

What is a Kiss Cut Sticker?

A kiss cut sticker is carefully cut from a vinyl sheet, but it does more than that. While many stickers are cut right through, the kiss cut makes sure only the sticker’s vinyl layer is sliced, leaving the backing whole. This cutting style gets its name from the delicate “kiss" the cutting tool gives, making sure it’s not too deep.

These stickers are made with high-tech machines—either laser or die-cutting—which are good at keeping the right depth. After printing your design onto a vinyl sheet, it goes through these machines. With pre-set settings, the machine’s cutting tool smoothly moves over the sheet, outlining the design’s shape while keeping the backing paper whole.

Pros of Kiss Cut Stickers:

- Easy to Use: The whole backing paper offers more grip, so it’s a breeze to peel and stick.

- Cost-friendly: Making them is simpler than die-cut stickers, which usually means better prices.

- Flexibility: You can stick them on your laptop, a window, or a notebook. They adhere seamlessly to various surfaces.

- Creative Freedom: With the machine’s precision, you can go wild with shapes, not just the usual ones.

- Toughness: Made of top-quality vinyl, these stickers can handle fading, scratches, and tearing. They might not last as long as die-cut stickers in tough situations but are strong for everyday use.

Cons of Kiss Cut Stickers:

- Aesthetic Concerns: The additional border, characteristic of kiss cut stickers, might not appeal to everyone.

- Comparative Durability: They might wear out quicker than die-cut stickers, especially if you’re tough on them.

- Visual Appeal: Die-cut stickers, cut right to the design, might have a fancier look.

What is a Die Cut Sticker?

A die cut sticker is a cool artwork. Unlike regular stickers with regular shapes, die cut stickers are custom-shaped the specific shape of the design. This means that both the vinyl layer and the backing material are precisely cut to match the sticker’s design, leaving no extra background or border.

The creation process mirrors that of kiss-cut stickers to an extent, but with an emphasis on precision. After transferring the design onto the vinyl sheet, it undergoes a specialized cutting machine. However, here, the machine is calibrated to slice through both the vinyl and the backing, resulting in a standalone sticker that embodies the design’s true form.

Pros of Die Cut Stickers:

- Unique Look: The precision of the cut, along with the absence of any background, gives it a pro look.

- Lasts Long: They’re made to last, especially when they get lots of handling, like on gadgets.

- Can Stick Anywhere: Made for all sorts of surfaces, they really shine where looks really matter.

- Keeps the Design: Every curve, edge, or detailed part of the design is kept, leading to the sticker you imagine.

Cons of Die Cut Stickers:

- Price: Being precise isn’t cheap. The custom cutting can bump up the price.

- Application Nuances: Due to the absence of any protective borders, one needs to be careful while applying to ensure that the edges adhere well and uniformly.

- Transportation Concerns: Without the protective backing seen in kiss-cut variants, they might be more susceptible to damages like creasing during transit.

Key Differences Between Kiss Cut and Die Cut

When comparing the main features of kiss cut and die cut stickers, it’s helpful to visualize their distinct characteristics side by side. Here’s a table to illustrate the differences:

| Feature | Kiss Cut Stickers | Die Cut Stickers |

| Cutting Depth & Precision | Cut only goes through the vinyl layer, leaving a border of uncut backing around the design. Offers protection especially during transit. | Cut goes through both vinyl and backing paper, yielding a custom-shaped sticker that exactly follows the design contours. Enhanced visual appeal. |

| Cost | Generally more cost-effective due to simpler cutting process. Only top vinyl layer is sliced, making production quicker. | Typically pricier due to the intricacies involved in the cutting process. Custom shapes require precision, leading to higher production costs. |

| Material Versatility | Adheres to a broader range of materials. Ideal for stickers, labels, and decals. Suitable for sticker collections on a single sheet. | More restricted in terms of material versatility. Unique shapes make them stand out. Preferred for branding, promotional materials, and packaging designs. |

| Applications | Perfect for situations where multiple stickers on a single sheet are desired or for simpler designs. | Ideal for situations demanding distinct designs, brand prominence, or when a custom shape can enhance branding. |

Which Type of Sticker is Right for You?

Choosing between kiss cut and die cut stickers isn’t just about the aesthetics; it’s about aligning with your specific requirements and budget constraints. Here’s a breakdown to help guide your decision:

- Purpose & Ease of Use: Kiss Cut Stickers are great choice if you’re venturing into stickers for the first time, want something user-friendly, or perhaps, planning a large-scale campaign with multiple designs on a single sheet, kiss cut stickers come out on top. Their surrounding backing makes them easy to handle, ensuring a clean peel and stick process.

- Budget-Friendly Option: Kiss Cut Stickers are great option if cost-effectiveness is a top priority, then you might lean towards kiss cut stickers. Their simpler cutting process translates to reduced production costs, making them a pocket-friendly option for large orders.

- Design Aesthetics & Durability: Die Cut Stickers are a perfect way when the design itself becomes the showstopper or if you aim for a unique shape to represent your brand or idea, die cut stickers excel. Their precision-cut profile offers a neat, professional finish, making them instantly more noticeable. Additionally, their robust build generally promises a longer lifespan, especially in high-touch situations like on gadgets or vehicles.

The choice between kiss cut and die cut stickers basically comes down to your objectives, what designs you like, and your budget. Kiss cut stickers are easy to use, cost-efficiency, and versatile, while die cut stickers showcase design intricacy, durability, and a standout visual appeal.

As you weigh these options, you might consider partnering with platforms like Merchize – a leading Print on Demand and fulfillment service. We can guide you with professional insights, ensuring your sticker choices effectively resonate with your branding or what you personally need.